The details of 5 old structures of burner is solved

Burner regards degree of a kind of automation as higher Electromechanical unifinication equipment, the function that comes true from its can divide for 5 old systems: The system sending wind, ignition system, system that monitor, fuel system, electronic-controlled system.

1, system sending wind

The function of system sending wind heats the air that zephyr of certain wind speed sends the volume in the room in Yu Xiangran, its are main the component has: Plate washer of controller of pipe of fire of gun of impeller of motor of housing, fan, fan, wind, air door, air door, diffuse dish.

Housing: It is burner the installs bracket and fresh air to receive wind channel main component of each component. Can divide from the point of the appearance for box type and gun type two kinds, majority of box type burner has the outer garment of a material that note model, and power is general and lesser, high-power burner majority uses fission type housing, it is gun type commonly. The compositive material of housing pledges gently for high strenth commonly alloy cast.

Fan motor: The movement that basically is fan impeller and high-pressured oil pump provides power, also a few burner use alone electric machinery to provide oil pump power. Certain small-power burner uses single-phase electric machinery, power is relatively lesser, major burner uses three-phase electric machinery, electric machinery rotates according to certain way only ability enkindle implement regular job.

Fan impeller: Rotate through high speed the wind pressure with enough generation in order to overcome obstruction of the chamber of a stove or furnace and chimney resistance, need in order to satisfy flaming to the air with firebox enough inbreathe. It is comprised by the columnar shape wheel of the lamina that spends of certain banking angle, its comprise material to pledge gently for high strenth commonly alloy steel, also have the product of the figuration that note model, all eligible fan impeller all have good dynamic balancing performance.

Wind gun fire is in charge of: Rise to conduct air current and the action that stabilize wind pressure, also be the component of the passageway that take wind, have flange of type of a coat and mouth connection commonly. Its comprise material to be high strenth and high temperature resistant alloy steel commonly.

Air door controller: It is a kind of actuating device, control the roll of air door plate washer through mechanical connecting rod.

Have controller of hydraulic pressure drive and controller of servo motor drive commonly two kinds, former work is steady, produce breakdown not easily, latter control is accurate, wind force change is flowing.

Air door plate washer: Main effect is to adjust the size that enters wind force in order to control into the size of wind passageway. Its comprise material to have note model and alloy two kinds, the plate washer that note model is sheet commonly piece form, alloy plate washer has sheet piece, double piece, 3 wait a variety of combination forms.

Diffuse dish: Its special structure can arise rotate air current, mix adequately what conduce to air and fuel, still have at the same time adjust 2 times the action of wind force.

2, ignition system

The function of ignition system depends on igniting the mixture of air and fuel, its are main the component has: Ignition transformer, Ignition electrode, cable of high pressure of electric internal heat.

Ignition transformer: It is the changeover component that high pressure of a kind of generation exports, its output voltage to be commonly: 2×5KV, 2×6KV, 2×7KV, output electric current is 15~30mA commonly.

Ignition electrode: The form that discharges high-pressured electric energy through electric arc is changed into light energy and heat energy, with pilot-ignition fuel. General form of characters or letters having sheet and fission type two kinds.

Cable of high pressure of electric internal heat: Its action is deferent electric energy.

3, the system that monitor

The function of the system that monitor depends on assuring the moving of burner safety, its are main the component has the blaze monitor, pressure monitor, temperature that monitor implement etc.

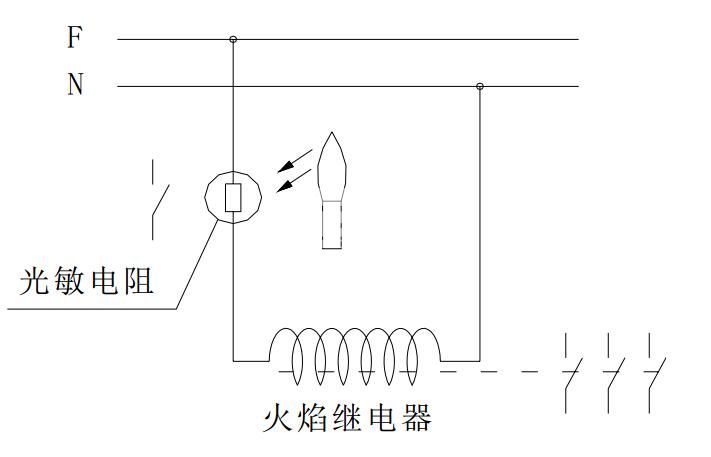

Blaze monitor: The formation that its main effect is surveillant blaze state, produce signal report program controller. Blaze detector basically has 3 kinds: Electric eye of photosensitive resistor, ultraviolet ray UV and ionization electrode.

Resistor of A, photosensitive: Multi-purpose go up at burner of light oil, heavy oil, its function and working principle are:

Photosensitive resistor and a blaze relay that have 3 contact are linked together, the block value of photosensitive resistor is followed implement of the light that receives how many and change, the light that receives is more, block cost is lower, should add in photosensitive resistor when the tension of two end is constant, the electric current in circuit is taller, when electric current reachs fair value, blaze relay is activationed, thereby enkindle implement continue to be down the job. When photosensitive resistor did not experience enough light, blaze relay does not work, burner will quit the job. Photosensitive resistor does not apply to aeriform burner, the blaze when burning because of gas is not quite bright.

Electrode of B, ionization: Multi-purpose go up at lighting gas burner. Program controller inputs 220V voltage to ignition transformer, two outputHigh tension lineOne of ground connection, another receives ignition electrode to go up, discharge produces electric spark between electrode and earth, ignite burn gas and air mixture, program controller gives ionization electrode power supply, if do not have blaze, the power supply on electrode will stop, if have blaze, burn gas by the high temperature ionization of its oneself, ionic electric current flows between electrode, blaze and combustion head, ionic electric current is become by rectification dc, the burner case that carries ground connection arrives at the job that blaze relay makes, go on wheels in order to make sure the foreword after burner works. If ionization electrode produces ground connection phenomenon, so the electric current of generation is dc of communication and rather than, blaze relay will not work, program controller lock is decided. In addition, ionization electric current and ignition electric current pass same ground connection circuit, because ignite electric current compares ionization electric current,get by force much, if flow direction of two kinds of electric current is contrary, ionization electric current will be ignited electric current is held back, after causing blaze to form, burner opened circuit however, this kind of blemish can be inputted reversely through ignition transformer will compensate, because receive electrical wiring hind instead, cause light a fire

The alternating current direction of transformer rotates 180° , the direction of ignition electric current of generation also rotates 180° , knot

If really direction of two kinds of electric current is consistent, such afore-mentioned blemish also are overcome namely. Additional, ionization area blaze is not stable

Also can cause the burner when blaze still exists to open circuit, because air lights gas to compare,the likelihood is improper, can

Through adjusting air is measured or light tolerance to solve, also may be the air on combustion head lights gas to distributing not all

Divide evenly, can burn through adjusting the position of the head will solve.

Electric eye of C, ultraviolet ray UV: Use at oil gas commonly on amphibious burner, this electric eye can experience the ultraviolet ray in blaze only (rice of accept of spectral limits 190~270) , UV is in charge of material of the glow inside won't solar to the fireproof material that twinkles inside the chamber of a stove or furnace, common light or furnace to make response, the life that UV runs falls to be 10000 hours about in the environmental temperature that does not exceed 50 ℃ , environmental temperature has very big effect high to its life too. If it accepts the ultraviolet ray of sufficient capacity, it can produce electricity, pass proper enlarge, machine or blaze relay, make it closes. If UV canal n is extinct, although nonexistent ultraviolet ray, it still can be shown received ultraviolet radiation, to overcome this one limitation, every time before open, program controller is met in its two end increase a proper tension, such although n is extinct, its signal can express to do not have blaze only, such program controller also quit the job with respect to immediately. To detect the effect of UV electric eye, after ignition it from former on take out at least one minute, after UV electric eye is taken out, do not detect the ultraviolet ray that gives out to blaze, relevant relay disconnects, burner quits the job. The inductive cell that although very few smeary metropolis holds off ultraviolet ray,enter the passageway of photoelectric cell and causes interior is not received misfire to the ultraviolet ray of sufficient capacity. Because this photoelectric cell must be cleaned clean thoroughly. UV canal experiences the light that is less than sun's rays or common lamps and lanterns, can use blaze or common ignition transformer the ignition flower between two electrode will detect its sensitivity. Work to ensure burner is normal, its electric current must be stabilized, the electricity that cannot need under program controller place. This electric current can use microamper plan to detect, its are worth cannot under pressure monitor: Use at aeriform burner commonly, basically high pressure burning gas, low pressure is monitored, and wind pressure is monitored, if burner is used at steam boiler, still vapour pressure is monitored.

Temperature monitor: Basically what smoke air temperature spends is monitor with control, fuel (heavy oil) of temperature monitor with control, and of systematic water and medium water temperature monitor with control.

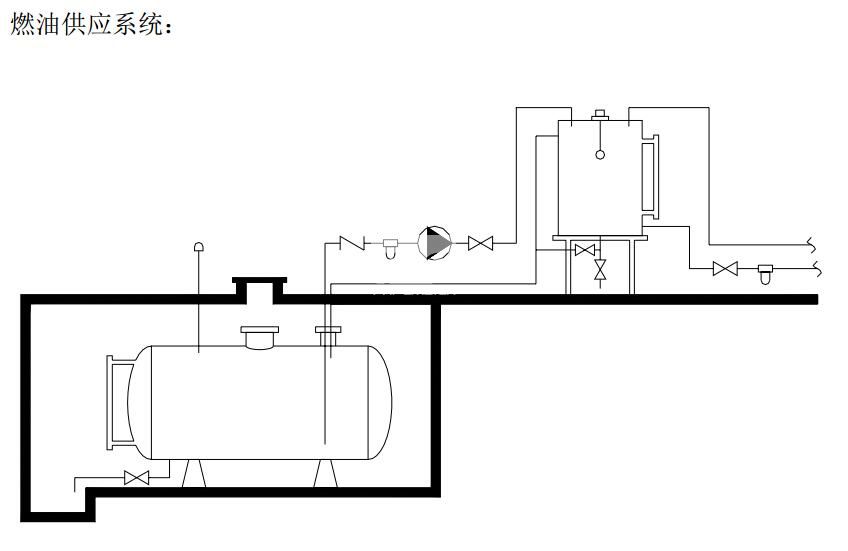

4, fuel system

The function of fuel system depends on the fuel that makes sure burner combustion place needs. The fuel system of fuel burner basically has: VittaReach a powerful person of contact, oil pump, electromagnetism, Nozzle, heavy oil intake air heater. Burner burning gas basically has group of a powerful person of electromagnetism of group of a powerful person of filter, booster, electromagnetism, ignition.

Vitta reachs contact: Use at transmitting fuel.

Oil pump: Produce the orgnaization of pressure oil, output oil pressure is in commonly 10bar above, in order to satisfy pulverization and the requirement that fuel injection measures, cent is in charge of output and double-barreled to output two kinds for sheet. Some burner oil pump and fan motor coaxial join, some have drive of alone oil pump electric machinery. Common oil pump has J model, E with TA model, apply to single pipe and double-barreled oily system, there are control valve of filter, pressure and shut-off valve inside oil pump. Filter basically is protective main transfer machinery, the mesh of E pump filter is bigger, when filter jams, can bring about vacuum excessive, filter wants to be cleaned regularly, clean or change after filter, must ensure pump lid is close together and sealed. Before oil pump is moving, must sucking note overflow of oily expect pump from side vitta fill, otherwise, because fight movement,pump is met and damage. The pump obstruction of oil pump air suction opening cannot exceed 0.4bar, the pressure that outputs a mouth is in commonly 10~24bar. The greatest pressure offerring oil of J pump is 20bar, the E the greatest pressure offerring oil with TA pump is 40bar, the biggest temperature that offer oil is 90 ℃ .

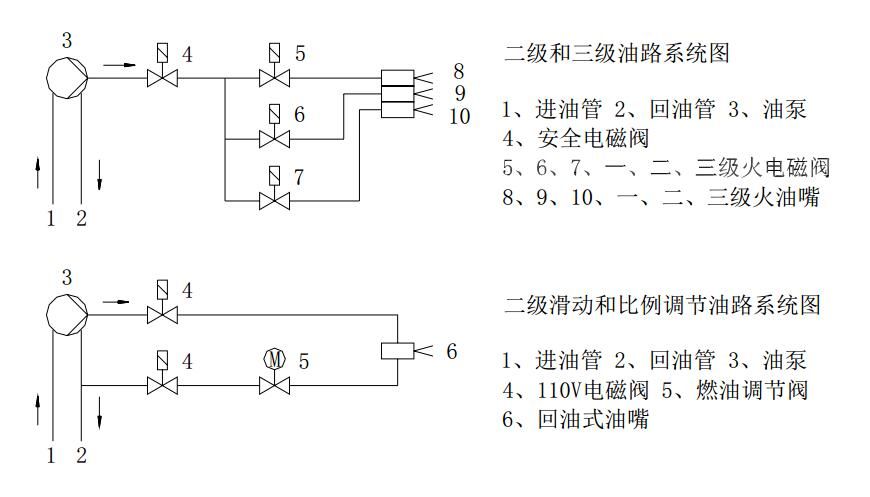

Electromagnetism a powerful person: Be used at controlling oil path connect, it is 2 a powerful person and 3 a powerful person more.

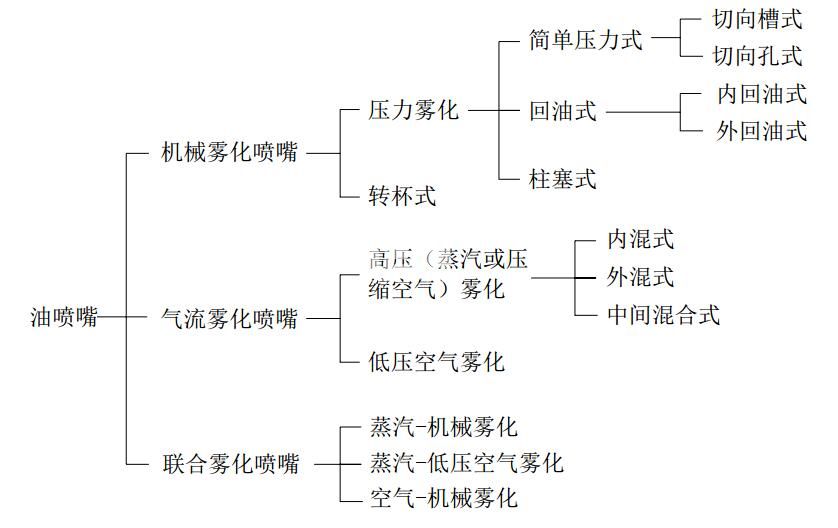

Nozzle: Main effect is pulverization oil drop. Oilymain parameter has eject part (30° , 45° , 60° , 80° ) , eject means (sincere, hollow, half hollow) measure with fuel injection. Below coequal pressure, the nozzle that lesser fuel injection measures, pulverization effect is better. Commonly used oily have nozzle of simple and mechanical pulverization and spray head of pulverization of machinery of the type that answer oil, former structure is simple, the system is simple, more reliable also, use at the burner of lesser bear commonly, latter structure and system want some more complex, but adjust character is good, when applying to boiler bear to often bigger range adjusts, use. Nozzle of simple and mechanical pulverization has tangential groovy type and tangential Kong Shi, former pulverization part is larger and pulverization grain is lesser.

Heavy oil intake air heater: The peculiar equipment of heavy oil burner, use at heating heavy oil comes constant temperature, reduce viscosity, in order to increase result of heavy oil pulverization, its temperature control equipment and burner control circuit are interlocking.

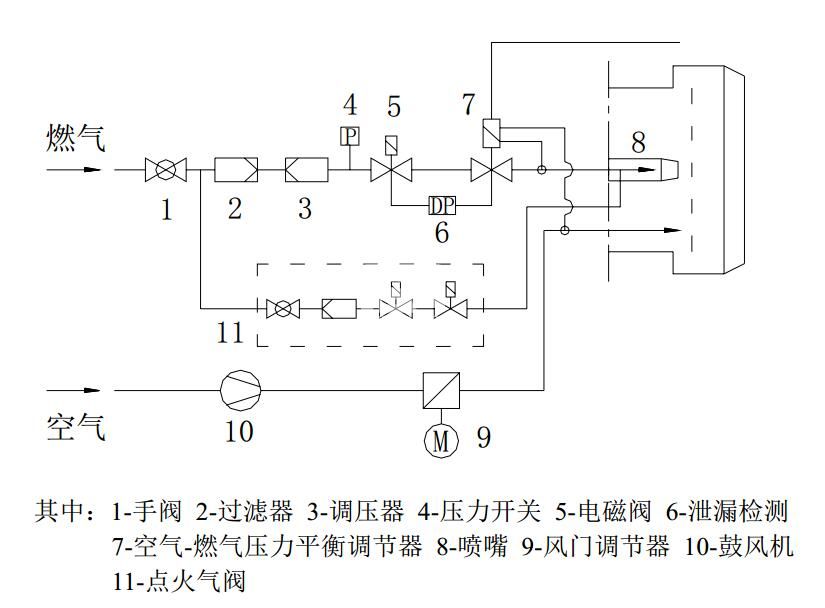

Filter: Its action is to prevent foreign matter to enter group of electromagnetism a powerful person and burner inside.

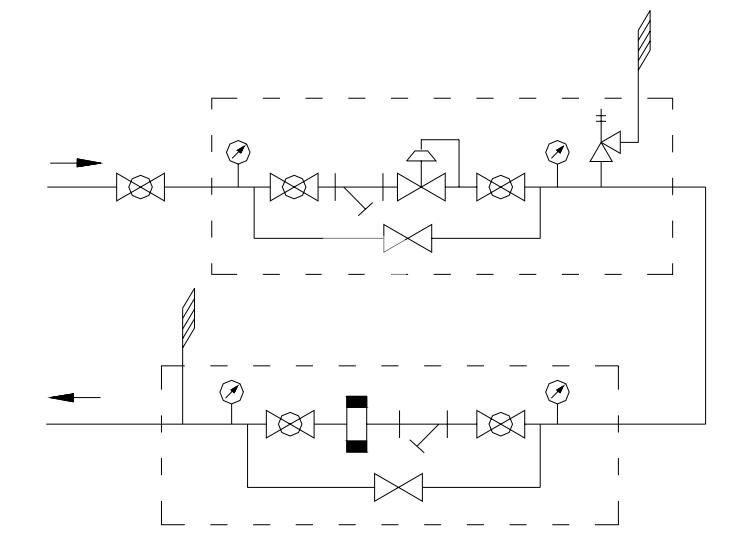

Voltage regulator: Main effect is step-down stabilized voltage, use in system of high-pressured air feed commonly, its entrance pressure cannot under 100mbar.

Group of electromagnetism a powerful person: Mix by safe electromagnetism a powerful person commonly advocate composition of electromagnetism a powerful person, have fission type and type of an organic whole, inter block of a powerful person of electromagnetism of type of an organic whole returns combination to have stabilized voltage a powerful person and screen pack commonly. Safe electromagnetism a powerful person shuts type quickly to leave quickly commonly. Advocate electromagnetism a powerful person is 2 level type commonly,

Detector of leak of electromagnetism a powerful person: Its action is to detect of group of electromagnetism a powerful person shut close. Go up with the burner that is more than 1400kw in power commonly.

Group of ignition electromagnetism a powerful person: Commonly the hand changes composition of a powerful person of ball valve, manostat, electromagnetism. Basically use at power bigger burner.

Light gas to supply a system:

5, electronic-controlled system

Electronic-controlled the system is above the command center of each system and contact center, main control component is program controller, deserve to have different program controller in the light of different burner, common program controller has: LFL series, LAL series, LOA series, LGB series, its basically distinguish the time that is each program measure to differ.

Burner job process introduces

With scale type burner burning gas is exemple, its job process has 4 level: Preparative phase, blow beforehand sweep level, ignition phase and normal combustion phase.

Plan stage: After program controller gets report, begin in-house program self check, in the meantime, drive air door goes to servo motor close position, after program self check ends, be in bide one's time condition, when constant temperature implement, exorbitant too lowLight baric power switch, when the limitative switch such as switch of pressure of steam boiler vapour allows, program controller begins to start, enter blow beforehand sweep level. IfElectromagnetism a powerful personGroup contain leak testing system, this system undertakes valve leak detect first when afore-mentioned limitative switch allow, detect after passing, just enter blow beforehand sweep level.

Blow beforehand sweep level: Air door of servo motor drive opens degree of position to conflagration, at the same time fan motor is started, undertake be blowinged beforehand sweeping with inbreathe air, according to program controller different, blow about after sweeping 20~40 second, air door of servo motor drive opens degree of position to ignition, prepare ignition. Whole blow beforehand sweep level, Air presses power switchMeasure air pressure, only air pressure maintains in enough on high level, blow beforehand sweep process ability to undertake continuously.

Ignition phase: After air door of servo motor drive opens degree of position to ignition, ignition transformer is cut, output tall voltage to give ignition electrode, in order to produce ignition electric spark, after about 3 seconds, program controller power transmission gives safe electromagnetism a powerful person and a powerful person of scale type electromagnetism, after a powerful person is opened, light gas to reach combustion head, the air that offers with fan mixes, be ignited next. Inside the 2 seconds after a powerful person is opened, ionization electrode should detect the existence of blaze, only such, program controller just continues the program from the back, otherwise, program controller lock is decided and disconnect electromagnetism a powerful person stops air feed, call the police at the same time.

Normal combustion phase: Ignition stabilizes combustion normally after a few seconds, air door of servo motor drive opens degree of position to conflagration, in the meantime, scale type lights those who enrage control valve dishServo electric machineryCut, adjust according to air pressure and back pressure of the chamber of a stove or furnace light those who enrage hind of a powerful person to light baric force to light tolerance in order to adjust, achieve goal of stable, efficient flaming. After this, burner realizes size automatically to fire is changed and stop according to limitting the demand of switch individually machine. In addition, in whole combustion process, ionization electrode and switch of empty baric power execute monitoring to burner.

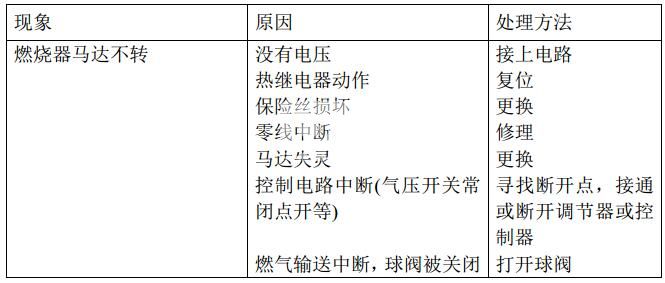

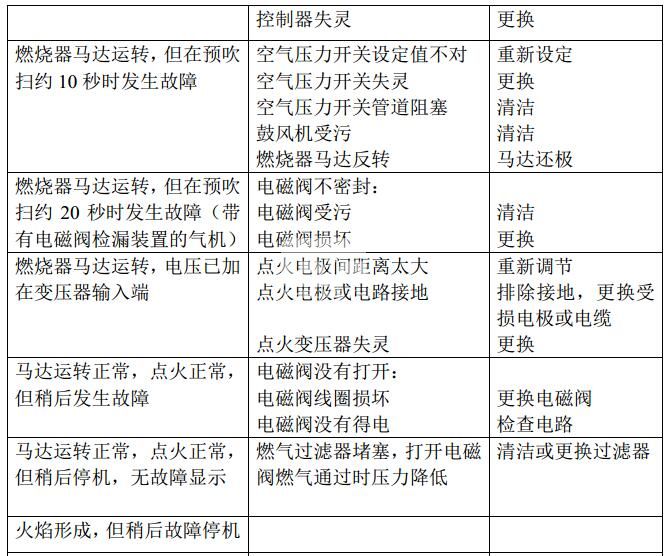

Common breakdown phenomenon, reason reachs a processing technique

When malfunction, the qualification that must check burner to run normally above all is contented:

1, is power supply normal?

2, it is normal that fuel supplies a system? It is normal to light baric force like what go up for tracheal path and whether is ball valve opened (air plane) ? Whether are there oil and the valve that answer oily conduit to go up for oil to open in gasoline tank (oily machine) ?

3, all adjuster andControlleradjust and is interlocking control normal? Like switch of attemperatior, discharge, water level switch, oil level switch, burn gasPressure switchEtc.

4, the empty tolerance when combustion and whether to light tolerance or fuel capacity to be changed?

If decide trouble is not caused by afore-mentioned reasons, must be oppositeBurnerconcerned function undertakes checking a test. Common method is take out certain and interlocking control, put through burner, watch process of the following job well and truly next, according to the phenomenon, can discover the problem is in immediately and eliminate.

Leave a comment